Block Movements

Occasionally blocks are moved from one warehouse to another.

Occasionally blocks are moved from one warehouse to another.

But most often they are moved from a warehouse to the production centre. If production sees the block almost fully utilised, then the remaining slabs or billets may remain in the yard. If a large part of the block remains and/or there is limited space for the remaining portion of the block, it must be moved back to a warehouse.

So there are several types of moves, each initiated from a different place in the software interface because they are for slightly different reasons.

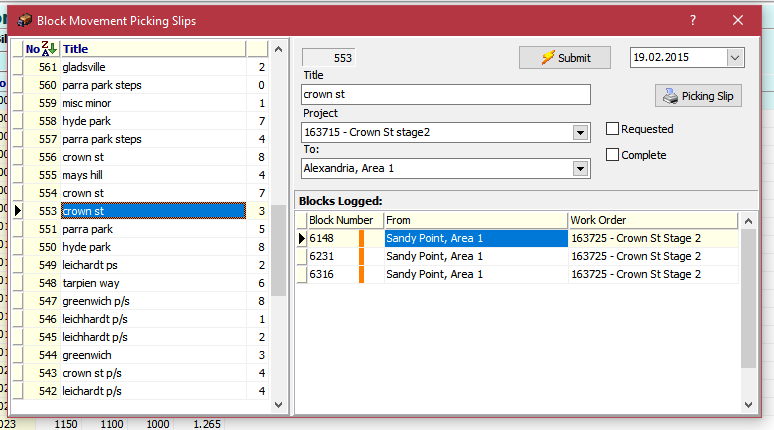

The block movements dialog provides for 2 stages in the movement process:

• Request, and then

• Completion

Whilst each movement assumes a single destination, blocks in a movement can be requested from multiple sources on the same picking slip.

Movements are also associated with specific Work Orders per block.

Requests

Commence a movement by first inserting  a New picking Slip. Provide a title for the movement/slip, associate a project and a destination.

a New picking Slip. Provide a title for the movement/slip, associate a project and a destination.

Then add blocks to what will become the movement request. Blocks are selected by block number in teh drop down menu. Once the block is selected, the source warehouse is inserted automatically. Select a Work Order for the purpose of accounting, from the drop down.

The block number column is marked by several colour bars which have the following key values:

• blue bar= the block is active

• red bar=the maximum transactions of 30 has been reached

• green bar=the block stone tag is attached to the stone (in theory)

• maroon bar=the block is declared as now partial volume from the original

• orange bar=the log is active for this block

Once the operator is satisfied that the movement request is complete, the movement is Submitted using the button at the top of the form.

Once the operator is satisfied that the movement request is complete, the movement is Submitted using the button at the top of the form.

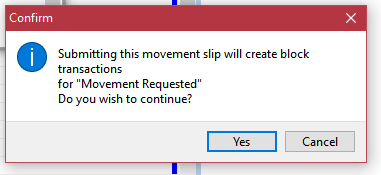

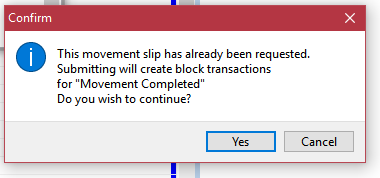

At this point PCC request confirmation that the movement shoudl move to a 'Requested' state. Once confirmed, transaction for the request will b created against the block in the Block Transaction file.

The movement will be marked as 'Requested' and a picking slip can be printed as part of the transport order.

This picking slip should accompany the order until delivery and then once signed off by the delivery agent, returned to the office.

Completions

When the slip is returned to the office and is presented signed by the receiving officer. the slip should be located in the list and re-submitted.

Once re-submitted, the movement will be marked 'Completed' and the associated transactions marking completion status are again entered against the block transaction list.

At this point, the movement request is finalised and will no longer appear by default in the list. To see it, turn the Filter on Active to OFF. The movement will be seen in the list.

Block transactions can also be located in the Inventory window for each of the slabs in the movement request.