Cost Monitor has provides a distribution list function where Purchase Orders, Correspondence and Variation submissions are broadcast not only to the required recipient (e.g contractor) but also to an additional list of recipients or CC’s.

On the Contact Details tab of each Project is a Distribution list. Names and email addresses are entered here as a permanent resources for people who may wish to receive copies of submissions as they are formally broadcast.

Enter your name and email address here if you want to be a part of the distribution list. Make your contact a primary contact if you wish to receive copies all submissions. If a contact is not marked as primary, you may still receive a submission by selection at the time of posting.

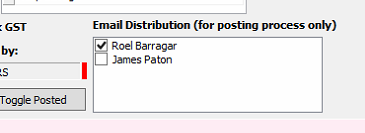

Contacts marked as primary are pre-selected int eh distribution list of the purchase order or Correspondence. Other contacts may still be selected (ticked) for particular submissions.

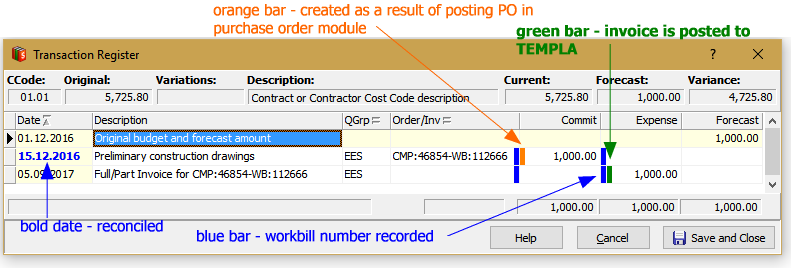

By including yourself in the CC list, a copy of the purchase order is delivered to your in-tray and becomes a permanent (dated) record of the order execution.